5s

+1

Submission successful!

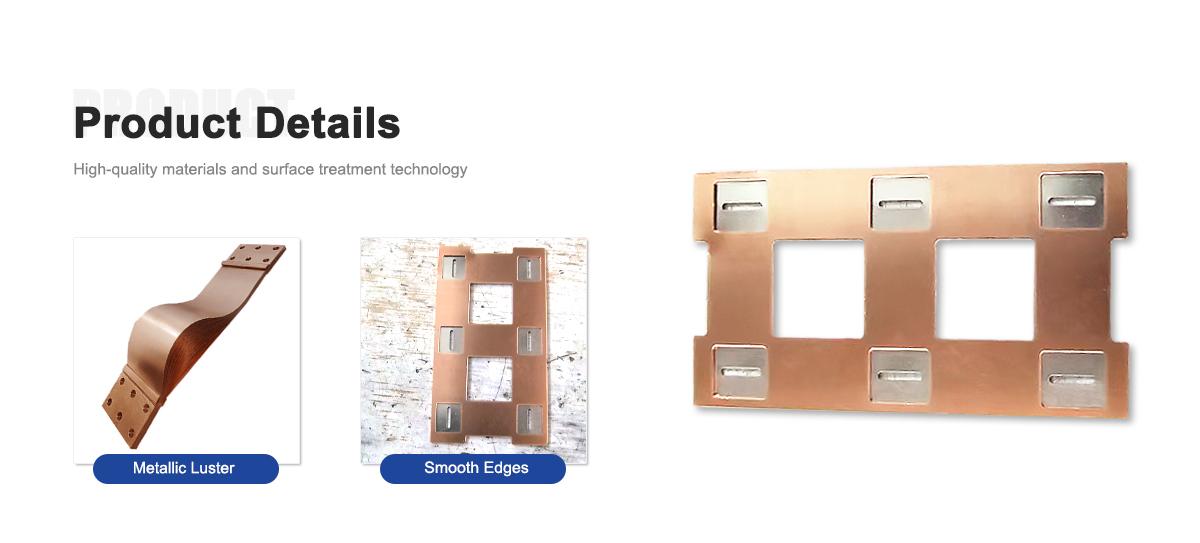

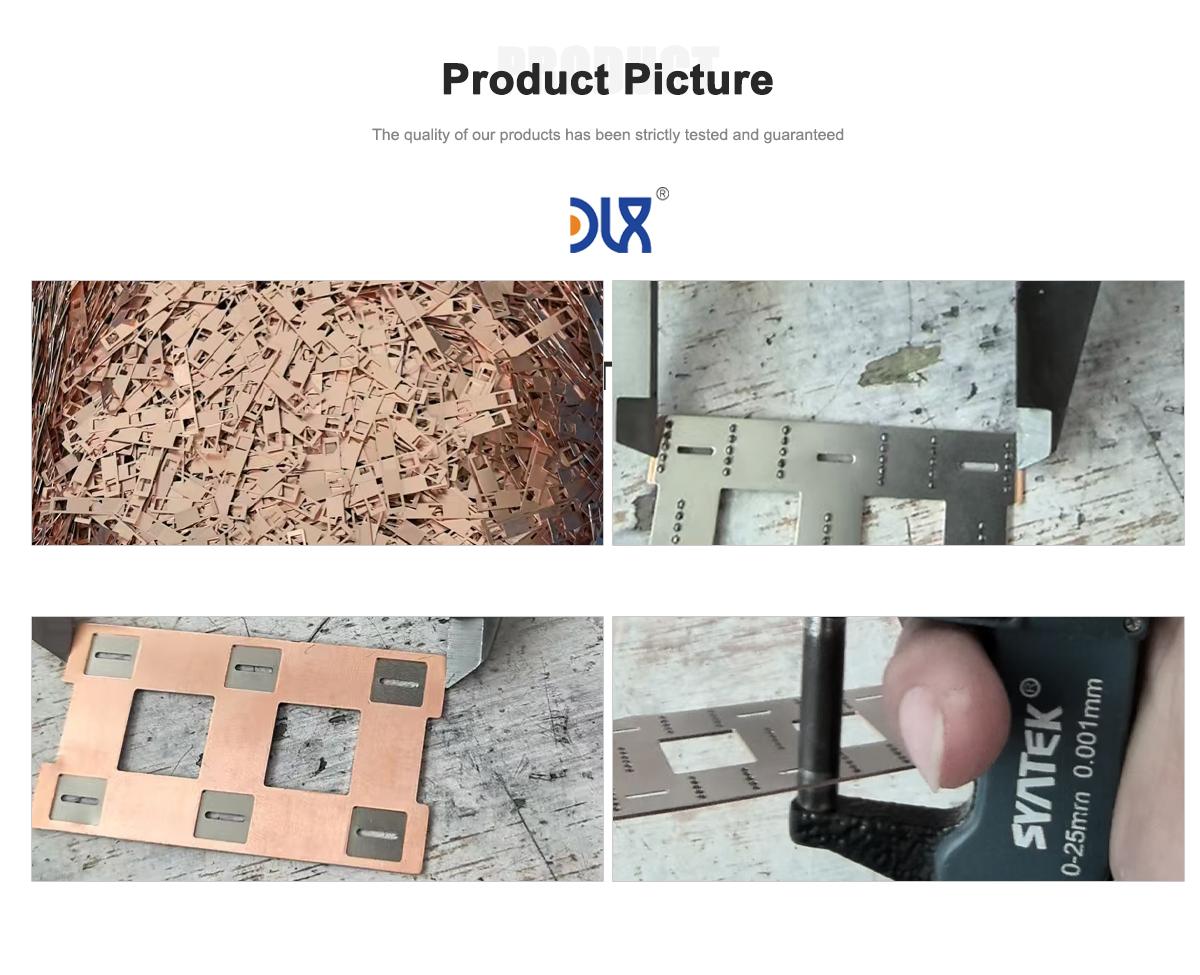

| Brand Name: | DLX |

| Model Number: | CuNi Busbar |

| MOQ: | 10kg |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union, |

| Property / Alloy Grade | МНЖМц30-1-1 (GOST) | C70600 (90/10 CuNi) | C71500 (70/30 CuNi) | Pure Copper (Cu) |

|---|---|---|---|---|

| Copper Content (%) | ~68–70 | 90 | 70 | 100 |

| Nickel Content (%) | ~30 | 10 | 30 | 0 |

| Iron (%) | ~1 | 1.5 max | 0.5 max | — |

| Manganese (%) | ~1 | — | — | — |

| Max Service Temperature (°C) | 200 | 200 | 200 | 150 |

| Corrosion Resistance | Excellent | Very High | Superior | Moderate |

| Electrical Conductivity (% IACS) | ~10–12 | ~21 | ~12 | 100 |

| Applications | Offshore energy, shipbuilding, desalination plants, industrial power grids | Marine systems, shipboard power | Chemical plants, offshore power | General power distribution |

| International Equivalents | GOST МНЖМц30-1-1 | ASTM B122 C70600 | ASTM B122 C71500 | ASTM B187 |