| Brand Name: | DLX |

| Model Number: | Copper Nickel Busbar |

| MOQ: | 15kg |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union, |

UNS C71500 70/30 Copper Nickel busbars are a premium choice for electrical systems that demand a balance of corrosion resistance, strength, and reliable conductivity. With 70% copper and 30% nickel, this alloy offers superior corrosion resistance in aggressive industrial and offshore environments compared to 90/10 CuNi grades, while maintaining sufficient electrical conductivity for power distribution applications. At DLX, we manufacture and supply C71500 busbars that meet stringent international standards, ensuring long-term performance for industries requiring dependable electrical infrastructure.

| Property / Alloy Grade | C71500 CuNi 70/30 | C70600 CuNi 90/10 | CuNi10Fe1Mn1 | Pure Copper (Cu) |

|---|---|---|---|---|

| Copper Content (%) | 70 | 90 | 88-90 | 100 |

| Nickel Content (%) | 30 | 10 | 9-10 | 0 |

| Max Service Temperature (°C) | 200 | 200 | 200 | 150 |

| Corrosion Resistance | Superior | Excellent | Excellent | Moderate |

| Electrical Conductivity (% IACS) | ~12 | ~21 | ~18 | 100 |

| Typical Applications | Industrial power distribution, offshore energy, chemical plants | Marine systems, shipboard power | Electrical connectors, industrial bus systems | General distribution |

| International Equivalents | ASTM B122, UNS C71500, DIN 2.0882 | ASTM B122, UNS C70600, DIN 2.0872 | DIN 2.0872 / CuNi10Fe1Mn1 | ASTM B187 |

The composition of C71500 makes it ideal for environments exposed to seawater, industrial cooling systems, and chemical plants. The high nickel content improves resistance to localized corrosion, stress corrosion cracking, and erosion, which are common challenges in industrial and marine operations. This alloy is particularly well-suited for high-demand electrical systems where both conductivity and durability are essential.

Compared to C70600 (90/10 CuNi), C71500 offers better corrosion resistance but slightly lower conductivity. This trade-off makes C71500 the alloy of choice for industries where environmental resistance is critical, such as offshore platforms, shipyards, and industrial plants handling aggressive media. DLX ensures that every C71500 busbar we deliver strikes the right balance between conductivity and mechanical integrity, offering clients durable solutions for challenging environments.

One of the key strengths of C71500 is its long service life in environments that would quickly degrade pure copper or aluminum. While copper has excellent electrical conductivity, it cannot withstand prolonged exposure to saline water or industrial chemicals without rapid corrosion. Aluminum busbars, although lightweight, lack the mechanical strength and corrosion resistance needed for long-term stability. By contrast, C71500 combines high durability with consistent electrical performance, making it a superior long-term investment for industrial and power distribution projects.

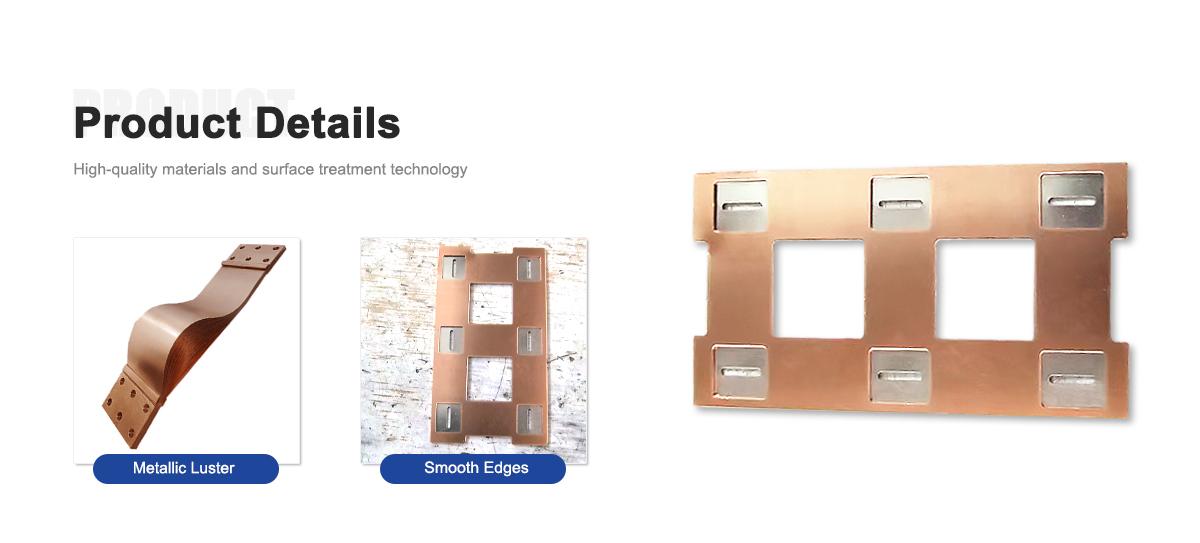

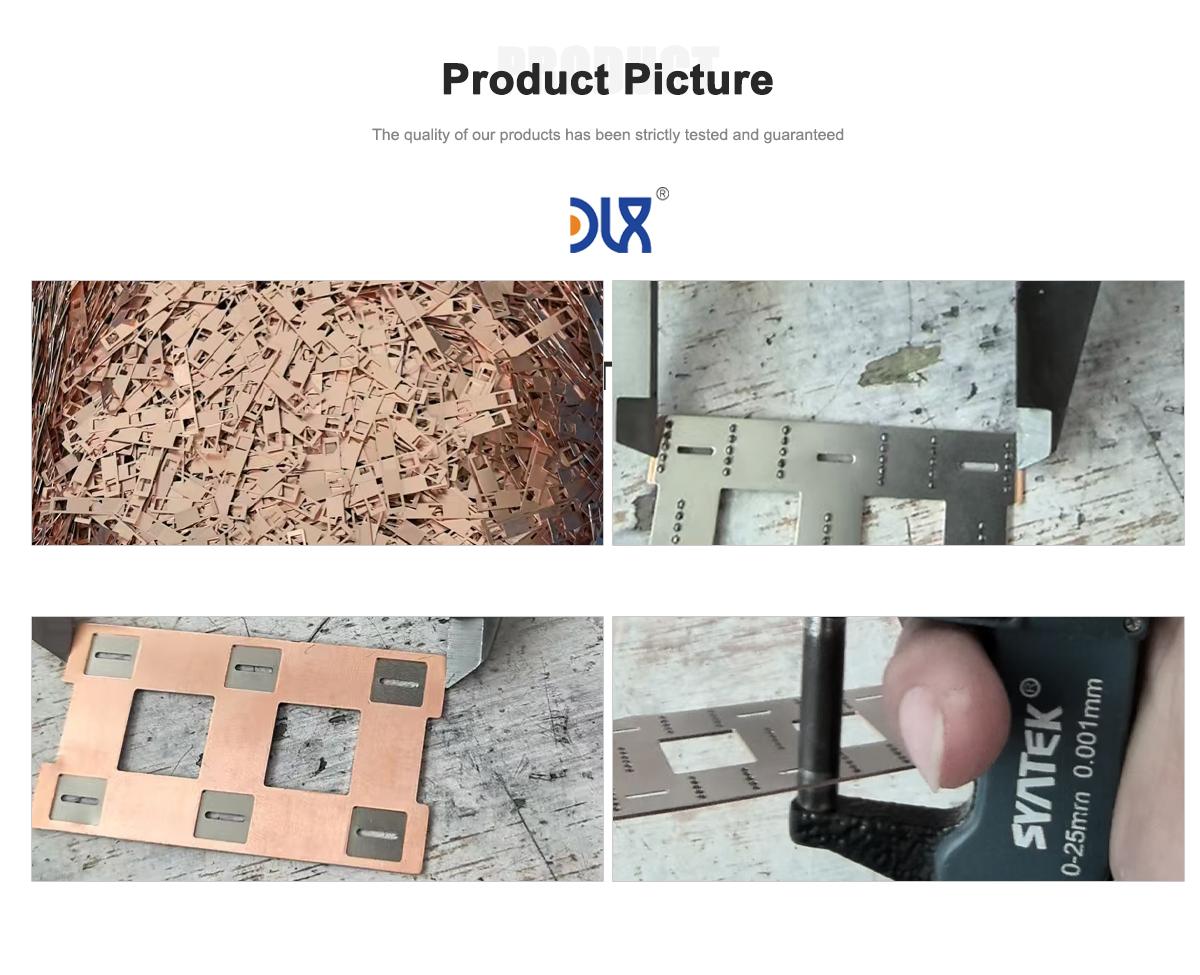

DLX manufactures C71500 busbars with precision, applying rigorous testing at every stage. Alloy composition is carefully verified to ensure compliance with ASTM B122 and DIN 2.0882 standards. Mechanical strength, dimensional accuracy, and surface quality are all inspected to guarantee that the final product meets or exceeds international specifications. This focus on quality gives our clients confidence that their systems will perform reliably under demanding conditions.

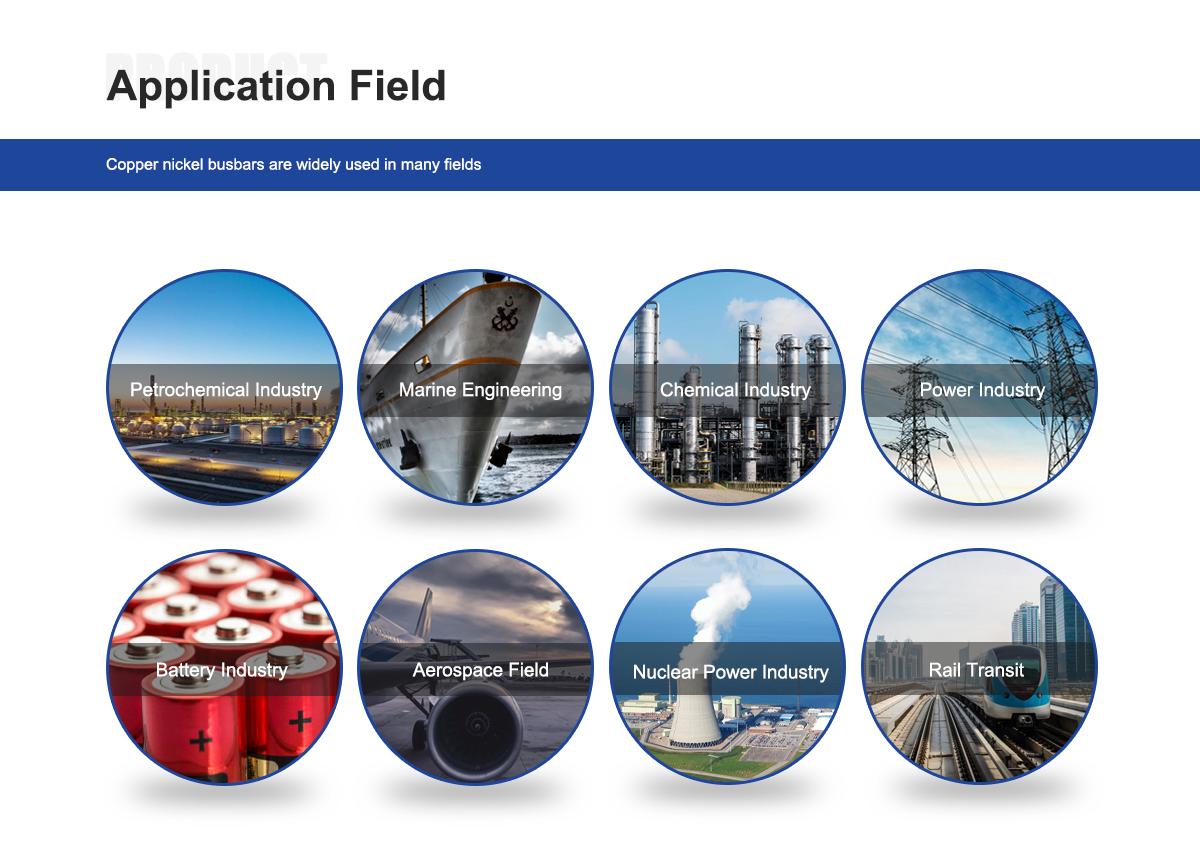

Applications for C71500 busbars extend across multiple industries. In offshore energy systems, they serve as critical components in high-current switchboards and grounding systems. In chemical and desalination plants, they resist corrosive agents while providing consistent conductivity. In industrial power distribution networks, they provide the strength and reliability necessary to handle heavy electrical loads. This versatility makes C71500 busbars a core material in advanced infrastructure projects around the world.

The industry trend is moving toward materials that not only deliver immediate performance but also reduce long-term maintenance and replacement costs. C71500 fits perfectly into this trend, offering extended lifecycle performance that reduces downtime and maintenance expenses. For industries where reliability and safety are paramount, investing in C71500 busbars ensures a stable power infrastructure that withstands harsh operating conditions.

At DLX, we differentiate ourselves by offering more than just high-quality alloys. We provide technical support to help customers select the most appropriate material and dimensions for their project. Whether it’s a large offshore installation, a chemical processing plant, or an industrial power grid, we help engineers and procurement teams make informed decisions that lead to better long-term results. Our global supply chain and efficient production processes also ensure timely delivery, reducing project delays.

Another key advantage of working with DLX is our ability to customize busbars to specific requirements. From precision cutting and bending to specialized surface treatments, we adapt our manufacturing processes to meet the unique needs of each application. This flexibility allows us to serve a wide range of industries with tailored solutions that maximize efficiency and reliability.

In power distribution, especially in harsh environments, the choice of busbar material is critical to ensuring consistent and safe electrical performance. With C71500 busbars, clients gain a solution that not only resists corrosion but also delivers mechanical strength and stable conductivity. Combined with DLX’s commitment to quality and service, this makes our C71500 busbars a trusted choice for international projects.

To summarize, UNS C71500 70/30 Copper Nickel busbars are an excellent choice for power distribution systems in challenging environments. They provide superior corrosion resistance, dependable conductivity, and long-term mechanical stability. With DLX as your supplier, you gain access to premium-quality busbars manufactured to the highest standards, supported by technical expertise and global logistics. Our C71500 products are built to perform, ensuring reliability and efficiency for industrial, marine, and offshore applications.

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Building Stronger Partnerships

We support all kinds of testing: